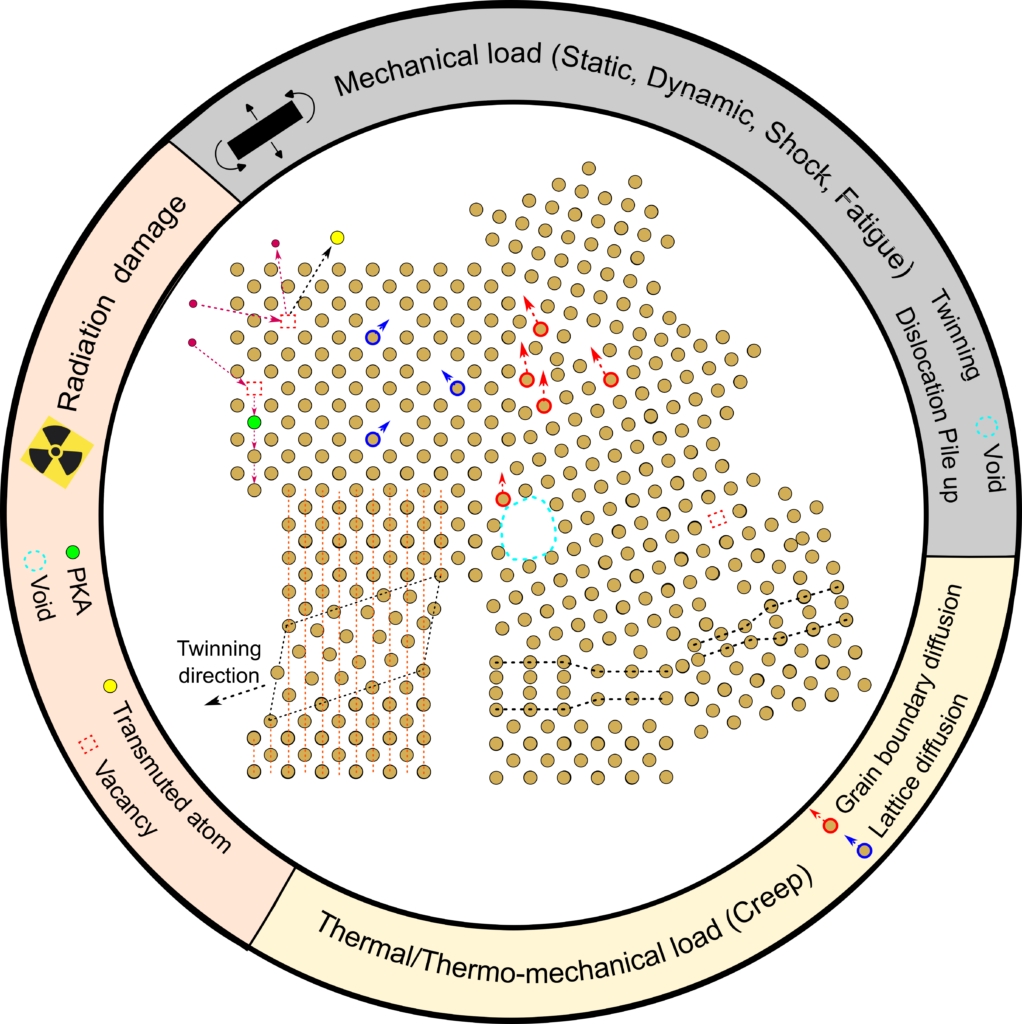

Metallic systems are profoundly affected by various types of energy, each presenting unique challenges to their stability and performance. A critical hurdle in creating the next generation of advanced multifunctional materials lies in the significant time investment required for their development and deployment, far exceeding the pace of material innovation.

To meet this challenge, accelerating the discovery, development, manufacturing, and deployment of advanced materials systems is the primary goal of the Materials Genome Initiative. Integrated Computational Materials Engineering (ICME) offers a roadmap to design new materials, yet crucial gaps in knowledge currently hinder its application for advanced materials like nanocrystalline (NC) alloys.

Our team addresses this gap by employing a multiscale modeling approach alongside detailed experimental methods and advanced manufacturing processes. This integrated approach aims to push the boundaries of material design closer to their theoretical limits.

For further insights, please refer below and to our detailed publications

Extreme creep resistance in a microstructurally stable nanocrystalline alloy

Nanocrystalline metals, characterized by grains smaller than 100 nanometers, exhibit superior strength at room temperature compared to their larger-grained counterparts due to significantly reduced grain size. However, this increased strength often comes at the expense of other mechanical properties such as creep resistance. Our research focuses on nanocrystalline copper–tantalum alloys, which uniquely combine high strength with exceptional creep resistance at elevated temperatures, while maintaining mechanical and thermal stability. Our approach to processing should facilitate the development of structurally stable alloys with exceptional strength and creep resistance, suitable for a wide range of high-temperature applications in aerospace, naval, civilian infrastructure, and energy sectors. see

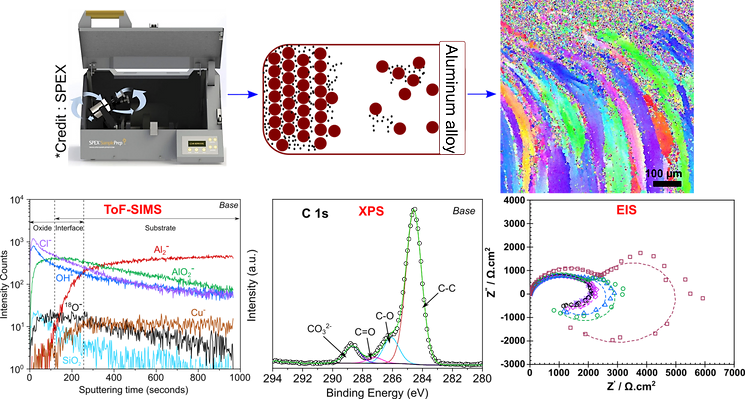

Gradient nanocomposite layer improved corrosion resistance of aluminum alloy

We explored the impact of surface mechanical attrition treatment (SMAT) on the microstructure and corrosion resistance of a high-strength aluminum alloy, leveraging gradient nano-grained structures to mitigate the strength-ductility trade-off. SMAT was conducted under room temperature and liquid-nitrogen (LN2) flow conditions to induce two distinct initial gradient microstructures. Our investigation included potentiodynamic polarization, electrochemical impedance spectroscopy, and intergranular corrosion tests. Surface film analyses using X-ray photoelectron spectroscopy and time-of-flight secondary ion mass spectroscopy techniques were employed to characterize untreated and treated samples. The results indicate significant microstructural alterations in SMAT-treated samples, including precipitate formation and dissolution of inherent phases. Notably, SMAT-treated samples exhibited a reduced rate of anodic dissolution. Furthermore, surface film characterization revealed a thicker oxide film enriched with Cu and SiO2 in SMAT samples.

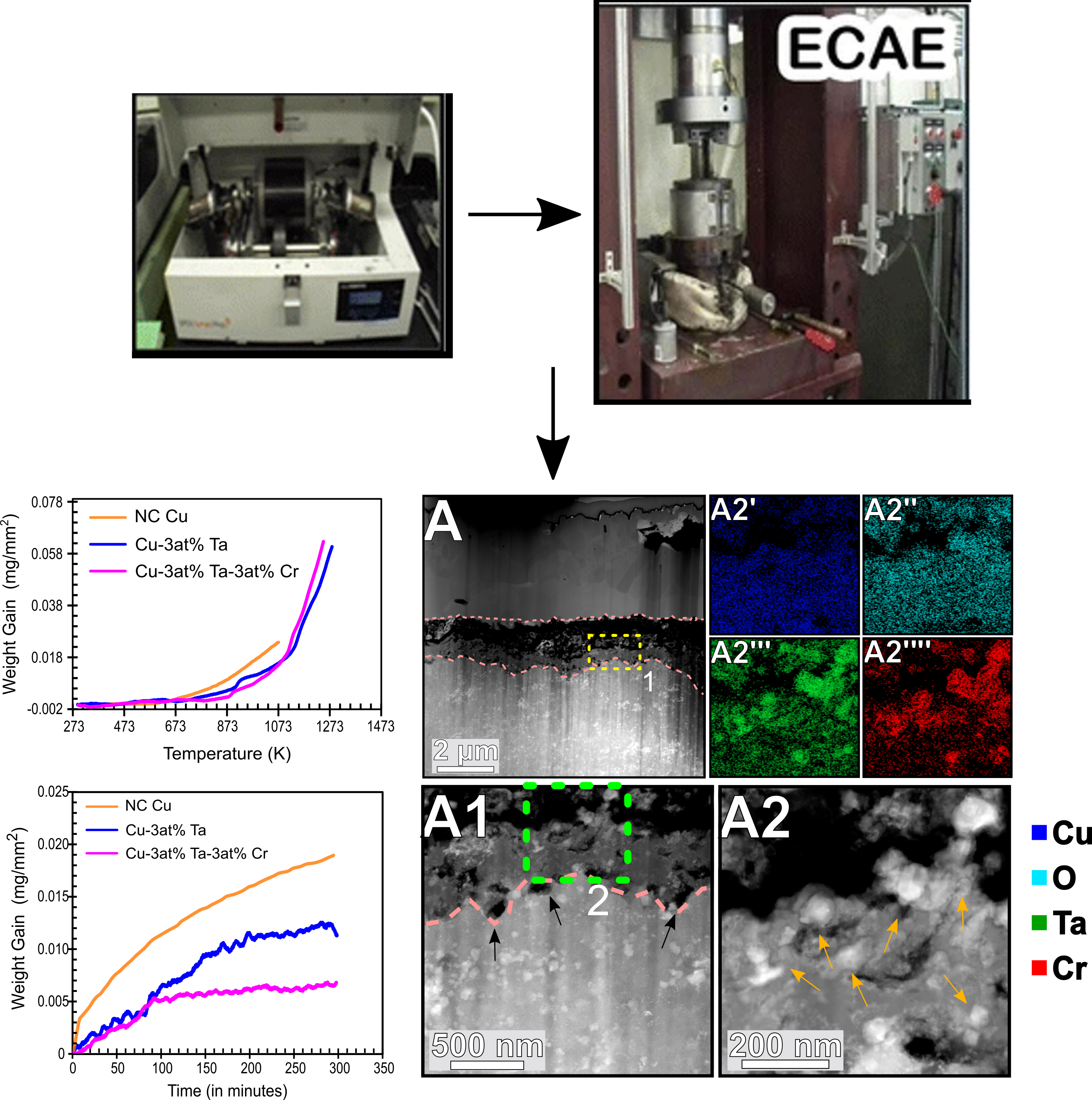

Investigating oxidation behavior of stable nanocrystalline alloys

The key features of NC alloys include enhanced mechanical strength due to their refined grain size and high-temperature microstructural stability that can be achieved through various thermodynamic and kinetic stabilization methods. However, the fine-grained structure that improves mechanical properties also makes NC alloys more susceptible to oxidation during practical applications. This increased vulnerability is due to the higher diffusivity of atoms resulting from the enhanced volume fraction of grain boundaries (GBs). By utilizing appropriate solutes that can form protective oxides on the alloys, this vulnerability can be turned into a beneficial aspect where faster diffusion would allow rapid development of oxide on the alloy surface and prevent further oxidation. Our research aims to systematically understand the oxidation mechanisms of these alloys under both dry and humid conditions. We are also exploring a multi-solute addition strategy to mitigate oxidation and improve the long-term performance of these alloys. This design approach provides a critical framework for developing high-strength, oxidation-resistant alloys for the energy and

transportation industries.

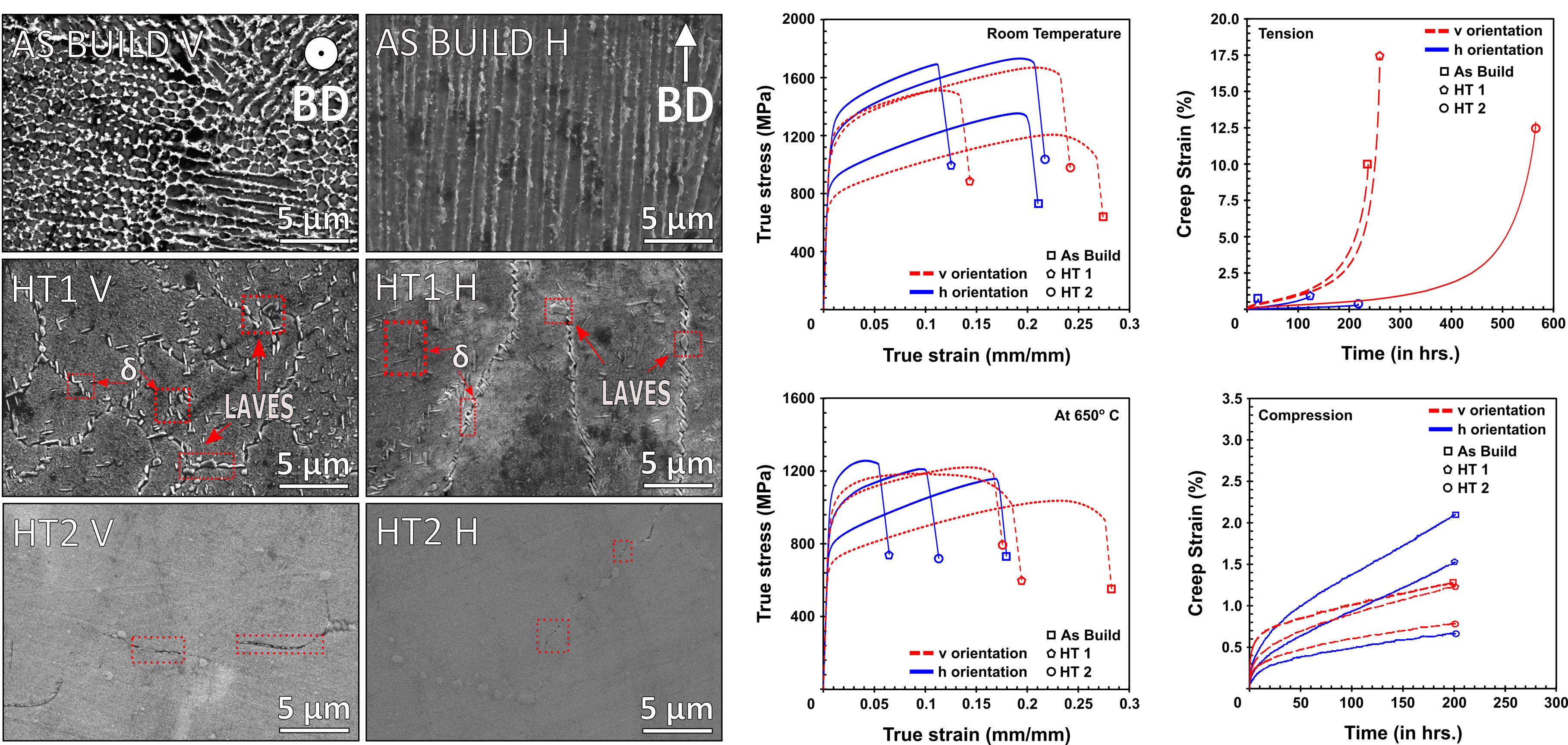

Process-induced effects on the mechanical behavior of additively manufactured alloys

Advancements in technology often introduce design complexities that limit the operational efficiency and conventional manufacturing capabilities of traditional alloys. Additive manufacturing (AM) offers a solution by enabling the production of near-net shape components. However, a comprehensive understanding of processing conditions, such as heat treatment, is essential for optimizing mechanical performance before practical application. Our research focuses on investigating how these processing conditions impact the thermo-mechanical behavior of AM alloys. We conduct quasi-static tests, high-rate tests, and creep tests under various loading conditions to thoroughly analyze the performance of these materials.